Introduction

In this article, we’ll explore smart factories examples from around the world, understand the technologies behind them, and discover how businesses — big and small — can join the revolution.

Ever imagined a factory that thinks for itself? A factory that learns, adapts, and evolves — not years from now, but today. Welcome to the age of smart factories examples — the backbone of Industry 4.0.

Smart factories are intelligent, connected environments where AI-powered robots, IoT devices, and machine learning come together to automate and optimize manufacturing in real-time. This is more than traditional automation — this is intelligent automation. And the world is taking notice.

What Makes a Factory “Smart”?

Smart Factories in a Nutshell

A smart factories examples uses interconnected systems and AI-driven robotics to enhance decision-making, reduce downtime, and increase productivity. Unlike traditional factories, smart ones are data-driven, agile, and responsive.

Key Features:

- AI-powered robotics

- Real-time data processing

- Predictive maintenance

- Seamless human-machine collaboration

The Evolution of Industrial Automation

From Manual Labor to Mechanization

Once upon a time, factories relied on sheer human muscle. Then came steam engines, followed by electric assembly lines. Automation started with machines doing repetitive tasks — faster, yes, but dumb as a rock.

Enter the Era of Robots

Robots changed the game. They were faster, more precise, and didn’t need lunch breaks. But early robots were rigid — they followed pre-programmed paths and couldn’t handle anything outside their script.

The Rise of AI-Powered Machines

Now, we’re in the AI era. These aren’t just robots — they’re smart robots. Think of them as Iron Man suits for factories. They analyse data, adapt to changes, and even learn from mistakes. This is no sci-fi fantasy. It’s happening right now.

Core Technologies Behind AI-Powered Robots

To understand how these intelligent systems work, let’s look at the core technologies that power smart factories examples.

Artificial Intelligence and Machine Learning

AI is the engine that drives decision-making. Machine learning lets robots learn from patterns, improve processes, and spot defects before they cause problems. It’s like giving your machines a brain.

Internet of Things (IoT) in Smart Manufacturing

Sensors, RFID tags, and connected devices constantly feed data into AI systems. This data — from temperature changes to machine vibrations — helps predict failures and optimize workflows.

Edge Computing and Real-Time Data Processing

Time is money in manufacturing. Edge computing allows data to be processed locally, at the “edge” of the network, so decisions can be made in milliseconds — no lag, no delay.

Computer Vision and Sensor Technologies

Vision systems allow robots to “see” what they’re working on. Combined with AI, they can inspect quality, read barcodes, or even navigate around obstacles. It’s like giving eyes and intuition to your machines.

How AI Robots Operate in Smart Factories

Decision-Making and Autonomy

AI-powered robots don’t just follow commands — they analyse data, predict outcomes, and make smart decisions. If a machine senses an overload, it can adjust settings or even reroute production.

Real-Time Monitoring and Maintenance

Smart robots come with self-diagnostic tools. They can detect wear and tear, notify maintenance teams, or even order their own replacement parts. It’s like having a robot doctor on call 24/7.

Coordination with Human Workers (Cobots)

Collaborative robots — or Cobots — work alongside humans. They handle heavy lifting or repetitive tasks, while humans focus on creative or decision-making roles. It’s teamwork, redefined.

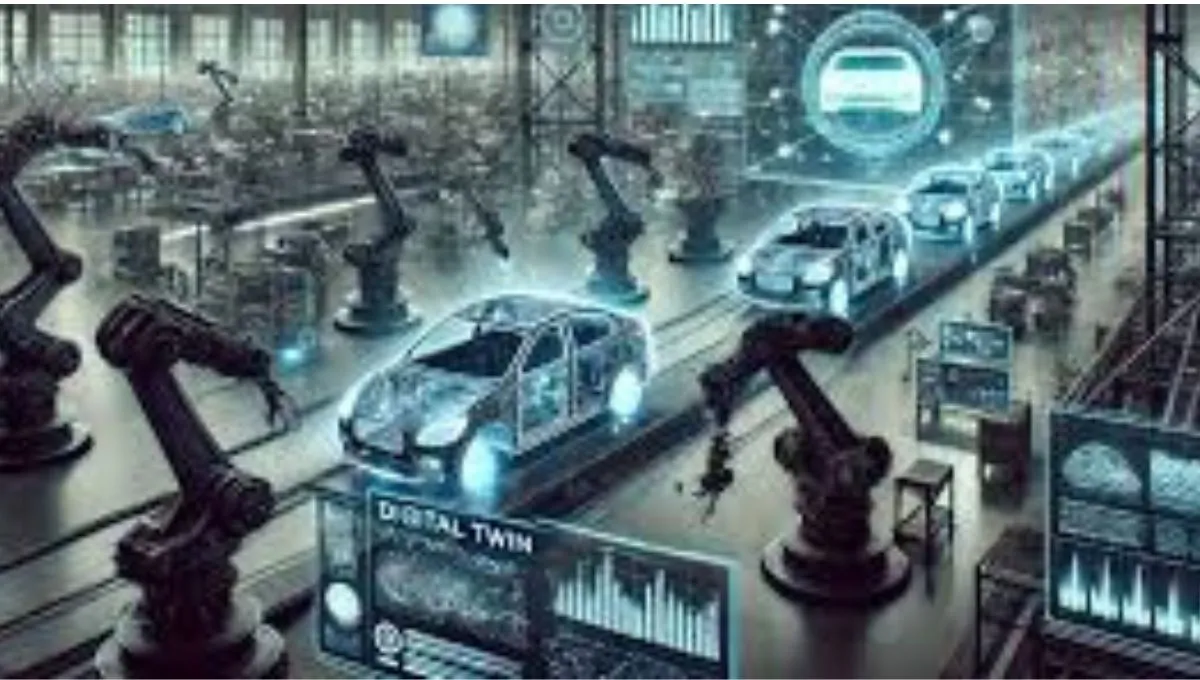

Smart Factories Examples That Are Changing the Game

Let’s explore some real-world smart factories examples that show how the future of manufacturing is already here.

1. Tesla Gigafactories – USA & Germany

Tesla’s factories use thousands of interconnected robots and AI systems to build electric vehicles with astonishing precision. These giga factories optimize themselves on the fly, adjusting based on real-time feedback.

2. Siemens Amberg Factory – Germany

With 75% automation, Siemens produces over 1,200 product variants daily with nearly perfect quality — 99.99885%. This factory is a poster child for Industry 4.0.

3. FANUC Robot Factory – Japan

FANUC’s factory is a robot-run robot factory. AI-driven machines assemble, inspect, and optimize without human intervention — showcasing full robotic independence.

4. Haier’s COSMO Plat – China

This smart factories examples of lets customers personalize appliances in real time. AI-driven lines reconfigure in minutes, supporting mass customization with no delay.

5. Schneider Electric Smart Factory – France

By combining digital twins, energy monitoring, and predictive maintenance, Schneider slashed energy use and improved system efficiency dramatically.

These smart factories examples demonstrate how AI, robotics, and data work together to create leaner, smarter, and more adaptive production lines.

Key Benefits of Smart Factories

Increased Efficiency and Output

AI robots never get tired. They work 24/7 with precision, reducing cycle times and increasing output significantly.

Reduced Human Error and Downtime

Machines don’t guess. With AI algorithms, decisions are based on data — not gut feeling — minimizing errors and avoiding costly shutdowns.

Predictive Maintenance

Why wait for a breakdown when your robot can tell you what’s wearing out — before it fails? That’s predictive maintenance in action.

Enhanced Worker Safety

By handling dangerous or repetitive tasks, robots reduce workplace injuries and create safer environments for human workers.

Challenges in Adopting Smart Factories

High Initial Costs

Setting up a smart factories examples isn’t cheap. The technology, sensors, and AI systems come with a hefty price tag — but the ROI usually justifies the investment.

Workforce Reskilling

Jobs aren’t disappearing — they’re evolving. Workers need to be trained in robotics, data analysis, and AI systems.

Data Security Concerns

With great connectivity comes great vulnerability. Cybersecurity must be prioritized to protect sensitive manufacturing data.

Integration with Legacy Systems

Bringing smart tech into old factories can be tricky. Retrofitting may require custom solutions and careful planning.

The Human-Machine Collaboration Era

Smart factories examples are not about replacing people. They’re about empowering them.

The Role of Cobots (Collaborative Robots)

Cobots are designed to work with humans — not replace them. They can hand over tools, assist in assembly, or double-check human decisions with data-driven accuracy.

Building a Synergistic Workforce

Imagine human giving feedback while a robot fine-tunes a process in real-time. That’s synergy — where human intuition meets robotic precision.

Ethical Considerations and Workforce Balance

How do we ensure fairness, privacy, and dignity in a robot-driven workplace? It’s a question every smart factory must answer.

Future Trends in Smart Factories

Hyper automation

This is automation on steroids — integrating AI, robotics, and software bots to handle entire workflows without human intervention.

Digital Twins

A digital twin is a virtual replica of a physical process or product. It helps simulate, predict, and optimize operations without risking real assets.

Self-Healing Systems

Think of it as robotic immune systems. These AI systems detect problems, isolate them, and fix them — often before humans even notice.

Cloud Robotics and 5G Integration

Faster networks mean smarter, more connected robots. 5G enables lightning-speed communication between devices and the cloud.

Smart Factories vs Traditional Factories

Feature | Traditional Factory | Smart Factory |

Decision Making | Manual | AI-driven |

Downtime | Frequent | Predictable & minimal |

Customization | Limited | Real-time personalization |

Data Use | Siloed | Integrated & actionable |

Case in Point: A traditional car factory might take weeks to switch models. A smart factories examples does it in hours with AI and modular robotics.

Case Study Comparison

A traditional auto plant might take weeks to reconfigure for a new model. A smart factories examples it can switch within hours using modular robotics and AI scheduling.

Industry-Specific Smart Factory Applications

- Automotive: AI robots weld, paint, and inspect vehicles with unmatched precision.

- Electronics: Assemble tiny parts like microchips under cleanroom conditions.

- Pharma: Ensure safe, sterile, and compliant drug manufacturing.

- Food & Beverage: Sort, pack, and inspect products at high speed and hygiene levels.

These industries offer some of the most advanced smart factories examples in the world today.

How Businesses Can Transition to Smart Factories

Assessing Readiness

You don’t need to jump in head-first. Start by analyzing your current processes and identifying areas ripe for automation. This smart factories examples of lets customers personalize appliances in real time.

Starting Small – Pilot Projects

Begin with one line or one process. Learn, iterate, and scale.

Choosing the Right Technology Partners

From cloud platforms to hardware vendors, picking the right allies makes all the difference.

Training and Change Management

Get your team onboard. Upskilling programs and open communication go a long way.

ROI of Smart Factory Implementation

Real Business Gains

Higher throughput, better quality, and faster time-to-market all add up to stronger profits.

Long-Term Sustainability

Smart factories consume less energy and produce less waste — a win-win for both business and planet.

Competitive Advantage

Those who adapt, win. Smart factories are the key to staying ahead in today’s global market.

Government Initiatives and Support

Policy Frameworks

Many governments are backing Industry 4.0 with strategic roadmaps and digital innovation programs.

Incentives and Funding

Tax breaks, grants, and subsidies are available to encourage adoption.

Global Collaborations

From Germany’s Industry 4.0 to Japan’s Society 5.0, countries are pooling resources to accelerate transformation.

Environmental Impact of Smart Factories

Energy Efficiency

Smart robots consume less energy by optimizing operations on the fly.

Waste Reduction

Real-time monitoring minimizes overproduction and material wastage.

Sustainability in Manufacturing

Cleaner processes, smarter logistics, and efficient use of resources help factories reduce their carbon footprint.

Final Thoughts: Are Smart Factories the Future?

You bet they are! The transformation is already happening, and those who embrace AI-powered robots will lead the charge into a smarter, safer, and more efficient industrial era.

Whether you’re just starting out or scaling up, the future belongs to those who innovate — and smart factories examples from around the world show exactly what’s possible.

Conclusion

In a world driven by speed, precision, and sustainability, smart factories examples are more than a trend — they’re a necessity. With benefits like precision, agility, and sustainability, they’re reshaping industries one smart decision at a time.

From the global giants like Tesla and Siemens to smaller factories experimenting with AI, the smart factories examples we explored today prove that the future of manufacturing is already here — and it’s powered by intelligence.

FAQs

Tesla’s Gigafactories, Siemens’ Amberg facility, Haier’s COSMO Plat, FANUC in Japan, and Schneider Electric’s smart factory in France are standout examples.

Not at all. Small and mid-sized companies can start with pilot projects and scale gradually using cloud-based AI and modular robotics.

Yes, they use energy more efficiently, reduce waste, and promote sustainable practices throughout the production lifecycle.

Robots work side-by-side with humans, assisting with repetitive or dangerous tasks and enhancing safety and productivity.

Begin by identifying bottlenecks in your current process. Then start small with one automated line, evaluate performance, and scale up with the right tech partners.